- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Plastik işleme şirketleri için toz çıkarma öğütme tablolarının avantajları nelerdir?

2025-05-08

Botou Xintian Environmental Protection Equipment Co., Ltd. is a manufacturer and trader.

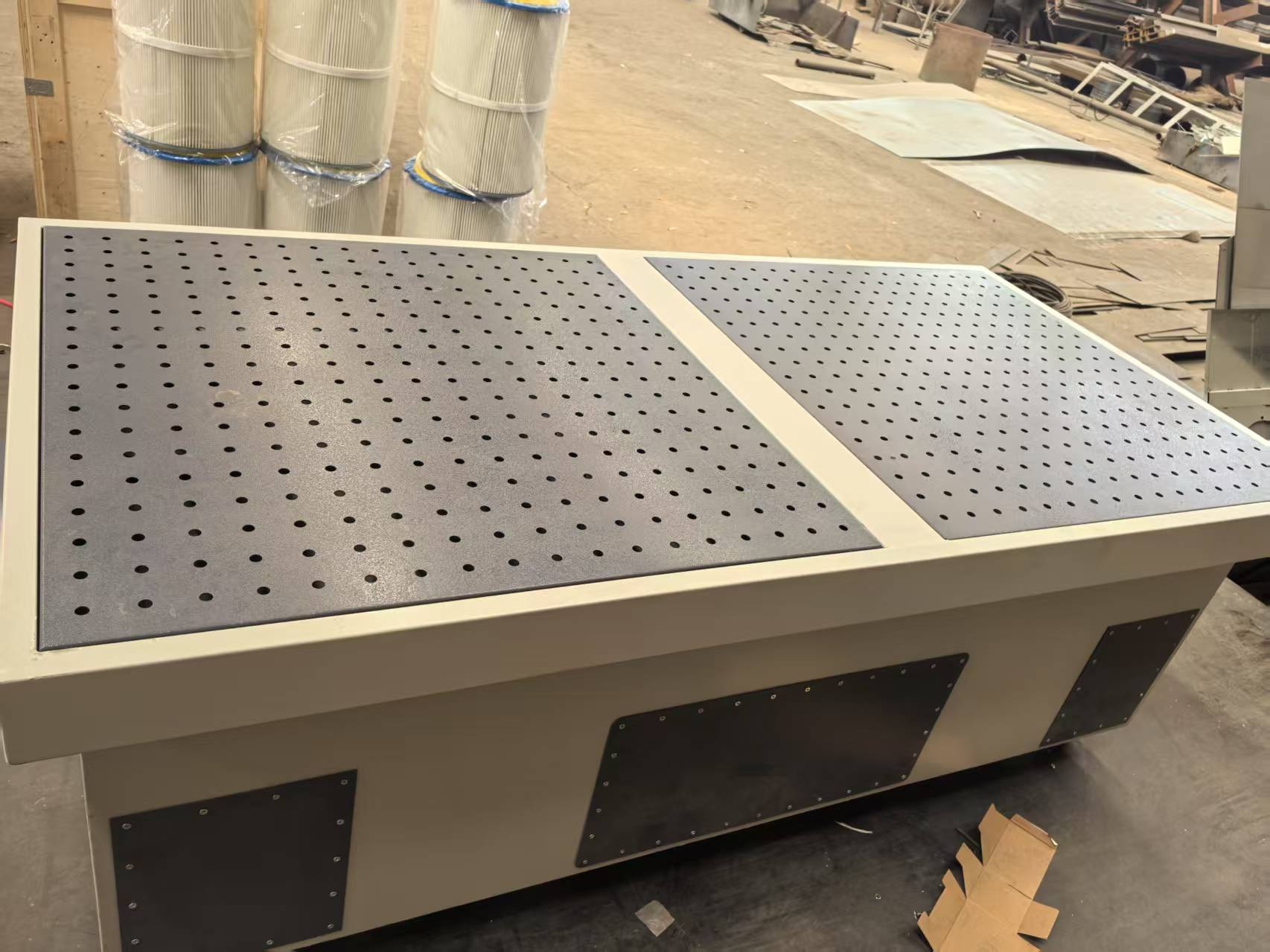

The dust removal grinding tables we produce are flexible, have high dust removal accuracy, and are easy to maintain.

The dust removal grinding tables have many advantages in plastic processing companies, which are mainly reflected in the following points:

- Precision grinding: The dust removal grinding table can provide high-precision grinding effects. According to the different needs of plastic processing, the plastic raw materials or products can be ground to a specific particle size and shape to ensure the product size accuracy and surface flatness, which helps to produce high-quality plastic parts and products.The dust removal grinding table achieves micron-level processing accuracy through a multi-axis linkage system, and accurately controls the material geometry and particle size distribution according to different plastic processing requirements. The high-speed rotating gradient grinding disc forms a variable pressure field on the contact surface, so that the polymer matrix can be directional cut according to the preset parameters, ensuring that the finished product has stable dimensional accuracy and surface morphology.

- Remove impurities: The built-in airflow stratification device constructs a negative pressure vortex in the crushing area, and captures free particles in real time through the combined action of electrostatic adsorption and inertial separation, blocking the cross-contamination path of processing debris and molding materials. This synchronous purification mechanism effectively eliminates surface microcracks and internal stress concentration points, so that the optical uniformity and structural integrity of the final product meet engineering application standards.

- Optimize the production environment

- Reduce dust pollution: A large amount of dust will be generated during the plastic processing process. The dust removal grinding table is equipped with an efficient dust removal device that can collect the dust generated during the grinding process in time, reduce the dust concentration in the working environment, meet environmental protection and occupational health and safety standards, create a clean and healthy working environment for employees, and reduce the harm of dust to employees' respiratory system, etc.

- Reduce fire risks: Plastic dust is a flammable and explosive substance. When it reaches a certain concentration in the air, it is easy to cause an explosion or fire when encountering a fire source. The dust removal grinding table reduces the concentration of plastic dust in the workshop by timely dust removal, thereby greatly reducing the risk of safety accidents such as fire and explosion, and ensuring the production safety of the enterprise. Flat vacuum sanding tables achieve safe production threshold control of polymer materials by establishing a dynamic balance mechanism for dust concentration. Suspended plastic particles have low flash point characteristics due to the increase in specific surface area, and their self-sustaining combustion tendency is exponentially amplified in a turbulent environment. The nano-scale debris generated by the grinding process enters the gas-solid separation device through negative pressure drainage, so that the dust load in the working area is always below the critical point of deflagration.

The synergistic effect of the multi-stage cyclone separator and the electrostatic neutralization module not only blocks the continuous distribution of the dust cloud, but also eliminates the ignition risk caused by frictional static electricity accumulation. The real-time monitoring differential pressure sensor triggers the airflow compensation mechanism to ensure that the oxygen concentration in the closed system deviates from the oxidizing environment required for the free radical chain reaction. This dual protection system of active protection and passive suppression effectively disintegrates the four-element coupling conditions of dust explosion and builds an intrinsic safety barrier from the source of energy release.

- Improve production efficiency

- Integrated operation: With a integrated operation, modern dust removal grinding tables are usually designed as integrated equipment, integrating grinding and dust removal functions, reducing the equipment's footprint and the intermediate links in the production process, allowing plastic processing companies to more efficiently layout and organize production, and improve overall production efficiency.

- Continuous and stable operation: high-quality dust removal grinding table has high reliability and stability, can run continuously for a long time, and reduce downtime caused by equipment failure. At the same time, its high degree of automation can realize automatic loading, grinding and unloading operations, reduce manual labor intensity and improve production efficiency.

- Reduce raw material waste: through precise grinding control and impurity removal, the dust removal grinding table can improve the utilization rate of plastic raw materials, reduce the waste of raw materials caused by unqualified raw materials or inaccurate grinding, and thus reduce production costs.

- Reduce equipment maintenance costs: due to the good dust removal effect of the dust removal grinding table, the wear and corrosion of dust on other parts of the grinding equipment is reduced, the service life of the equipment is extended, and the maintenance and replacement costs of the equipment are reduced. In addition, a good working environment also helps to reduce the failure of other production equipment caused by dust pollution, further saving the company's equipment maintenance costs.